HSM TriShredder 6060 HSM TriShredder 6060 3-stage shredding unit with three cutting units and a... more

HSM TriShredder 6060

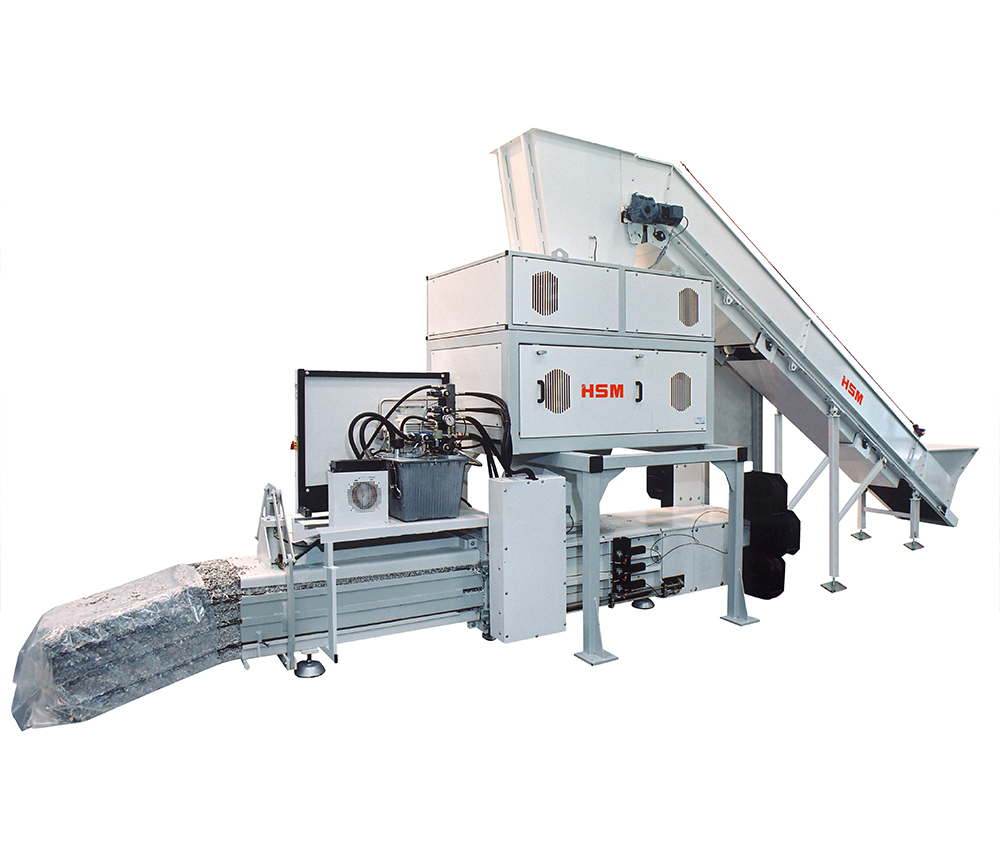

HSM TriShredder 6060 3-stage shredding unit with three cutting units and a throughput of up to 2500 kg/h at security level P-3. In combination with a baling press, you can expand the HSM TriShredder 6060 into a complete disposal system.

Three-stage fully automated shredding system.

Stage 1: pre-shredding using a four-shaft system consisting of two intake shafts and two cutting shafts.

Stages 2 and 3: fine shredding using a two-shaft system.

Sturdy loading hopper with built-in overloading protection to control the shredder and the conveyor belt.

The entire system is controlled automatically.

Reliably shreds whole lever arch files and telephone books.

The material can be loaded with a conveyor belt or discharge chute.

Can be used as a complete disposal system in combination with an HSM balling press.

Equipped as standard with energy saving frequency-regulated drive.

Optionally available with material collection trolley for solo operation, volume approx. 320 litres.

Modern PLC control unit for integrated control of all system components.

System compatible with HSM fully automatic baling systems.

Technical data "HSM TriShredder 6060 - 4.6 x 34 mm"

| Order number: | 1560001 |

| Cutting type: | particle cut |

| Cutting size: | 4,6 x 34 mm |

| Security level (DIN 66399): | E-3|F-1|O-3|P-4|T-4 |

| Intake width: | 650 mm |

| Shredder material: | Paper, Staples and paper clips, Credit card, Folders |